- 西甲最新积分战报 黑马输球皇马10分领跑 毕尔巴连胜超马竞进前4(2024-03-27)

- 篮球——NBA常规赛:湖人胜雄鹿(2024-03-27)

- 詹姆斯缺阵湖人险胜雄鹿,拉塞尔一战封神,佩林卡倒吸一口凉气(2024-03-27)

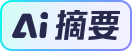

- 上港亚冠需当心小组最强对手 J联赛冠军客场完胜(2020-06-01)

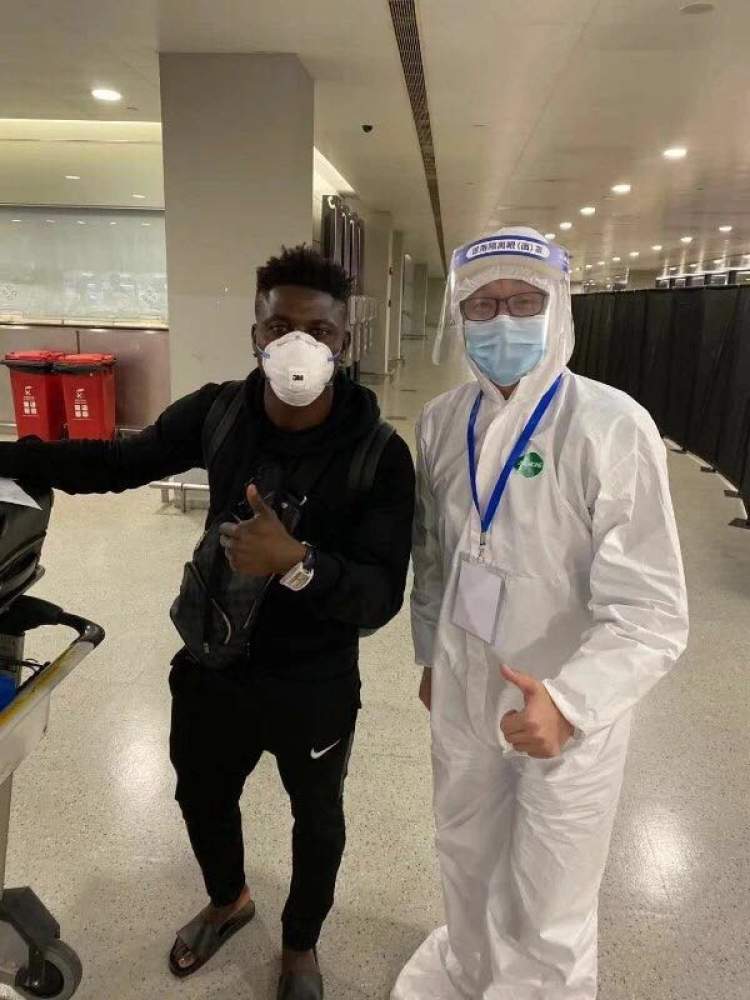

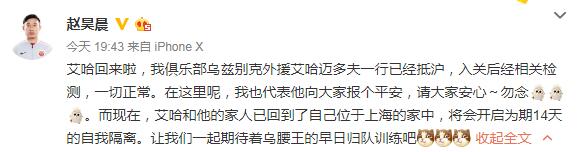

- 亚冠前瞻:国安两将伤缺还有更大隐患 特殊时期拒(2020-06-01)

- 国安VS清莱联首发:比埃拉回归搭巴坎布 杨帆迎首(2020-06-01)

- 国安主帅:望胜利能让大家有信心战胜困难 将给球(2020-06-01)

- 国安防线两大将无缘亚冠首战 金泰延疑似肋骨骨(2020-06-01)

- 亚冠最新赛程:中超队再度调整 涉及恒大上港国(2020-06-01)

最新发布